Development Areas (Main business)

An automobile is composed of numerous parts and components. Extremely high technology is needed to arrange such parts and components into an automobile. In all areas relating to the development, we are able to develop all of the parts and components that an automobile is composed of, taking on the responsibility of developing a whole vehicle, and possessing the technology necessary to put it all together.

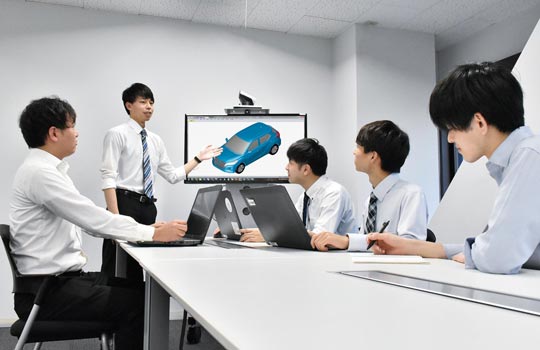

Creating attractive products

In order to develop attractive products, we create the vehicle concept and design based on the research on the environmental change and lifestyle. And we conduct the overall automobile design, including engine, vehicle body, interior/exterior parts, chassis and electronic components to achieve both design and functional performance. We offer reliable products that bring excitement and joy for driving.

Design

For realizing design attractiveness in production, we develop “Design model”, “Production design”, “Final styling data” and guarantee “Product quality”.

Vehicle project management

Fully coordinate the entire vehicle development process (cost, quality, performance etc.) to promote effort to achieve the target and organize the overall project planning through materializing the various ideas to provide comfortable spaces and efficient packaging.

Body design

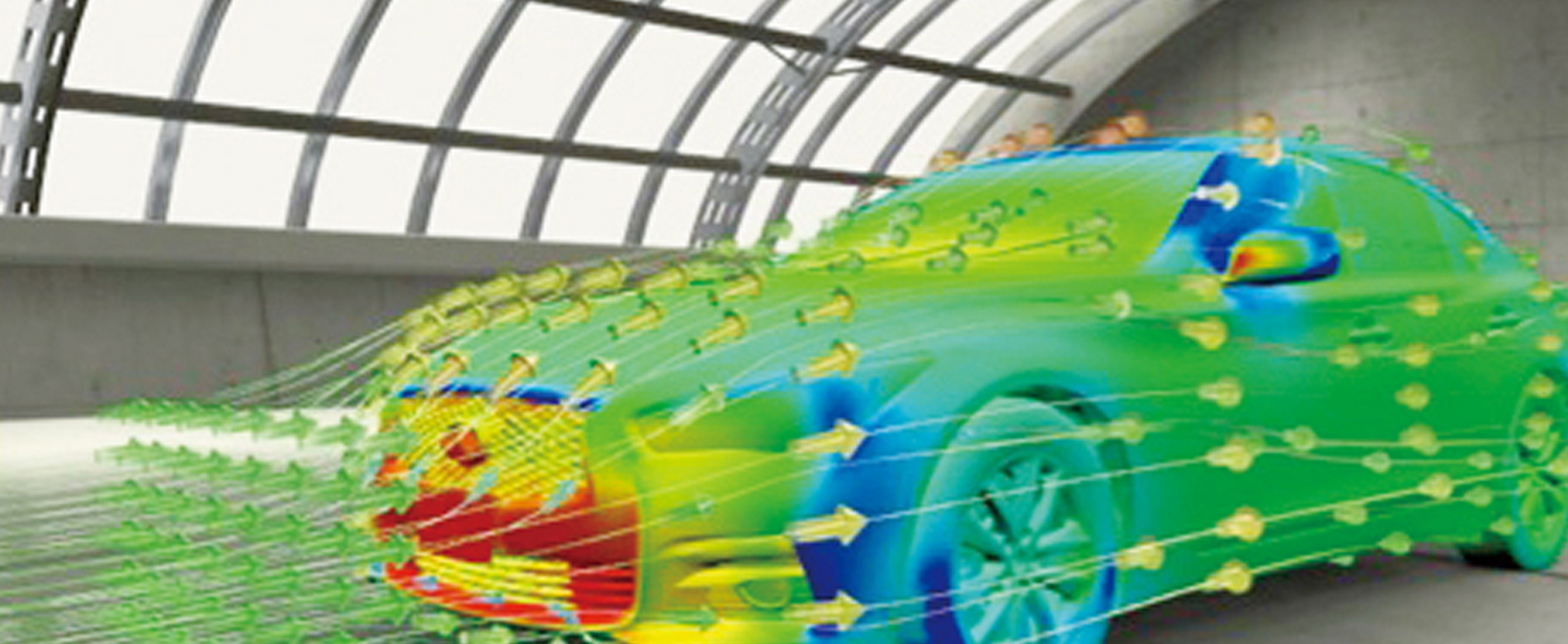

Responsible for body design for automobiles. Based on the styling data, design the body structures which satisfy various performance requirements such as strength, durability, safety performance and quietness by using CAE analysis.

Interior and Exterior design

Developing Interior and Exterior components which contribute to the impression of the vehicle. Working together related team Styling or Product planning, develop well balanced product, applying system engineering.

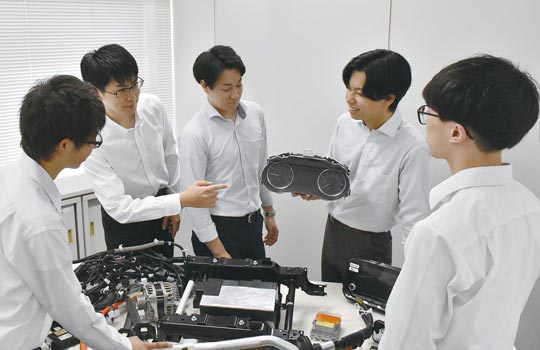

Electronic design

Our department is in charge of a design, the electronic system development design and evaluation, analysis of the electronic electric equipment parts of the car. We provide a comprehensive development process from basic planning to detailed design and project management for electronic control parts installed in vehicles to meet customer needs.

Connected car service, AD/ADAS design

Developing Connected and Autonomous in CASE technologies. Connected design uses IoT, AI and cloud technologies to develop CCS components. Autonomous design uses cutting-edge sensing and control technologies to develop autonomous driving and driving support systems.

Chassis design

Provide driving pleasure and secure handling by planning the dynamic performance and NVH performance, and developing parts design, analysis, layout study and CAD data.

Powertrain design

To proceed whole development of the engine (the heart of vehicle) and drivetrain components (transmit power to wheels), from performance planning to packaging, CAE analysis and project management.

Electric powertrain design

Responsible for the designing of "lithium ion battery" "Driving motor" which are indispensable for the performance of Nissan electric vehicles. Contribute to enhance the attractiveness of electric-operated vehicles globally with our technology strength.

Development support

(Homologation)

Make it possible for Nissan Group to introduce products into worldwide markets, through development support activities such as homologation documentation for each country.

World-leading quality and efficiency

CAD technology development propulsion

We are creating CAD data (Parts shapes, Drawings) of Nissan vehicles ALL OVER THE WORLD, working with Body design and Interior/Exterior design teams. In addition, we are also working on “Enhancement of vehicle development through CAD data utilization” by research, development and application of state-of-the-art CAD technologies.

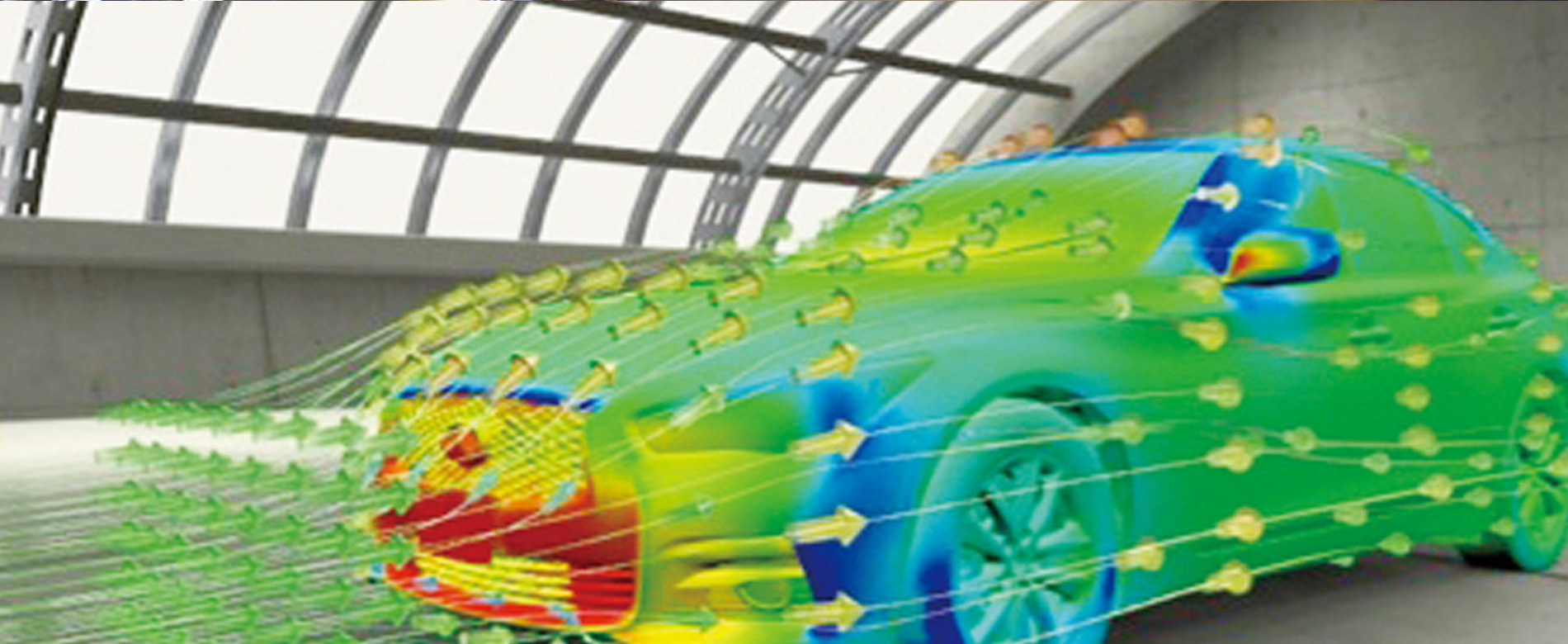

Vehicle analysis

Conduct the hypotheses verification with simulation by adopting various CAE software from the initial phase of development. Contribute to the early delivery of high quality vehicles to our customers through performance improvement and proposal to minimize the cost and mass.

Digital production engineering

Conduct simultaneous production engineering to secure mass production process for high quality vehicle with high efficiency. Through this simultaneous engineering in each production process (Stamping, Body, Paint, Plastic, T&C), develop vehicle design and process design with all design department to achieve all of production operation to stabilize quality and realize high value added operation with good ergonomics.

Realization of trusted automobile

Vehicle testing

The task of vehicle testing section is to achieve the vehicle performance targets as the final stage of vehicle development that exceeds the customer's expectations level. We ensure all vehicle performance by a combination of technical approaches and experimental skills.

Electronics testing

Electronic and electrical technology supports vehicle function such as EV/e-POWER, ProPILOT, etc., and is getting more and more complicated. We test these by using prototype parts and vehicles from early stage in development and provide new vehicle with reliability.

Powertrain testing

Contribute to producing high quality automobiles that achieve trust of customers and offer the joy of driving by implementing test evaluation and analysis of powertrain region, represented by engine, EV motor and drive-train, as well as durability, reliability, drivability performance and exhaust emission performance of vehicles.